Mobile Cleanrooms

Pacific Environmental uses its 35+ years experience in cleanroom design and cleanroom construction to provide innovative solutions to your cleanroom requirements. Whether your needs are driven by mobility requirements, temporary applications, time or space constraints – we can provide you with a completely equipped and furnished cleanroom environment.

What is a mobile cleanroom?

As the name suggests, mobile cleanrooms are fully-capable cleanroom systems designed to be portable and deployed at the point-of-use. Mobile cleanrooms can be constructed on a range of platforms, including portable modular structures (like a mobile office), retrofitted trailers and vehicles, or built into standard ISO shipping containers for durability and ease of shipping. All mobile cleanrooms generally have the same features and functionality of a traditional modular cleanroom system, including compliance and ISO certification, but are self-contained and can be easily relocated to wherever they are needed. Depending on the application, mobile cleanrooms can be completely self-contained and have fully-integrated mechanical, plumbing, and electrical systems with optional power generation and other required ancillary systems.

Types of Mobile Cleanrooms

While mobile cleanrooms are all fundamentally the same in operating principle, there are several factors to consider when selecting the type of mobile cleanroom you require. This is generally affected by the desired location of the cleanroom, its intended application, and environmental considerations (e.g., indoor vs. outdoor).

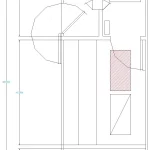

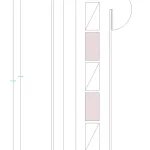

- Mobile Modular Cleanrooms: This type of mobile cleanroom is constructed using an existing modular structure as a platform. The interior is then retrofitted according to the customer’s design specifications, regulatory requirements, and application. Once construction is complete and the cleanroom has passed testing and certification, the entire structure is then transported via flatbed to its final destination where is it generally erected on footings or a foundation.

- Mobile Cleanroom Trailers: Offering the ultimate in portability, cleanroom trailers are towable or drive-able trailers or vehicles that have been retrofitted to provide a cleanroom environment. Typically having all required systems on-board, cleanroom trailers are generally fully self-contained with mechanical, plumbing, electrical, HVAC, and control systems integrated.

- Containerized Cleanrooms: Constructed inside a standard shipping container, this type of mobile cleanroom is excellent and withstanding harsh environments. Because if its uniform ISO size, it can easily be loaded onto the flatbed or shipped anywhere worldwide for a relatively modest cost. Additionally, several units can be combined in a multi-unit configuration to create larger areas, areas of differing classifications, or to provide expandability and scalability as your needs grow.

Mobile Cleanroom Classifications and Regulations

Each type of mobile cleanroom has all the same features and functionality of a modular cleanroom system, and can be designed to meet your specific industry requirements. Ranging from ISO 5 to ISO 8 (Class 100 to Class 100,000), each mobile cleanroom can be segmented into areas of differing classifications, can be outfitted with gowning areas and anterooms, and can have the required mechanical, architectural, and plumbing systems required to comply with USP 797 & 800, BSL-2 and 3, cGMP, and many other regulatory guidelines depending on your intended use application.

| Classification vs. Air Changes per Hour (ACH) | |||

| ISO | FED STD 209E | cGMP | Air Change Rate (ACH) |

| ISO 8 | Class 100,000 | Grade D | 25-35 ACH |

| ISO 7 | Class 10,000 | Grade C | 40-60 ACH |

| ISO 6 | Class 1,000 | 75-120 ACH | |

| ISO 5 | Class 100 | Grade B1, A | 250-300 ACH |

| ISO 4 | Class 10 | 400-600 ACH | |

| Filter calculation based on classification and ACH. Required Filters = Room Volume x ACH / 6502. | |||

| 1 Grade B cleanrooms have a higher allowable particle count during operation, but equivalent allowable particle count at rest. 2 Note that average filter output can vary between 600 and 750 CFM depending on manufacturer and internal room pressure. | |||